DDM for Medical & Life Sciences

Compliance-Ready PLM for Regulated Environments

In the medical, biotechnology, and pharmaceutical sectors, product lifecycle data must meet uncompromising standards for traceability, documentation, and control. DDM (Design Data Manager) provides a structured, audit-ready PLM system that supports full compliance with regulatory mandates.

We are trusted by:

Features of DDM

Powerful features to manage your Workflow.

In medical and life sciences, compliance isn’t a feature — it’s a baseline. DDM helps teams stay aligned with FDA 21 CFR Part 11, ISO 13485, and EU MDR — with everything from structured approvals to electronic signatures.

Whether you build Class III medical devices, manage biotech trials, or handle complex documentation for combination products — DDM ensures traceability, control, and confidence.

BOM + DHF + DHR Management

Maintain complete, audit-ready records for product design (DHF), manufacturing history (DHR), and multi-level assemblies (BOM) — all essential for FDA and ISO compliance.

Electronic Signatures & Audit Trails

Capture approvals with full traceability, timestamped logs, and Part 11-compliant electronic signatures — a core FDA requirement.

Gated Workflows & QA Controls

Enforce structured review and approval processes across design and quality checkpoints — aligned with ISO 13485 expectations.

Integrated Data Environment

Connect CAD, QMS, and ERP systems to create a single source of truth — reduces errors and ensures consistency across regulated documentation.

Cloud or On-Prem Deployment with Validation Support

Flexible hosting options with GAMP 5-aligned validation support — suitable for regulated environments and inspection-readiness.

Achieve Compliance Without the Chaos

Capture every change, approval, and document in one traceable system. Whether you’re working to ISO, FDA, or internal standards, compliance is structured, auditable, and stress-free.

Boost Team Productivity

Keep everyone aligned with a single source of truth. Engineers spend less time managing data, and more time solving problems and innovating.

Cut Engineering Costs

Remove time wasted on chasing files, duplicating effort, or fixing miscommunications. DDM simplifies design workflows and eliminates manual overhead.

Reduce Waste & Increase Part Reuse

Easily find, track, and re-use existing components instead of reinventing them. Fewer duplicates, fewer errors — more value from every design.

Build a Smarter, More Scalable Process

Replace disconnected spreadsheets and legacy tools with a future-proof system that grows with you — from prototype to global release.

Get Products to Market Faster

With connected data, streamlined reviews, and fewer handoff delays, teams move from concept to production without hold-ups or rework.

Why Choose DDM?

When it comes to managing product data and processes, not all PLM systems are built equally. Here’s what sets DDM apart:

75+

countries have manufacturing teams running DDM.

95+

of users say DDM improved version control and compliance

30+

years of development, trusted by SMEs and global manufacturers alike.

60%

of DDM customers replaced spreadsheets or file servers.

Proven Over Decades

With over 30 years of development and refinement, DDM has been shaped by real-world use across industries. It’s stable, trusted, and here for the long haul.

Built by Engineers, for Engineers

DDM focuses on what matters: control, clarity, and affordability. No bloated enterprise pricing or unnecessary complexity, just powerful tools that work the way engineers do.

Flexible, Not Fragile

Whether you’re scaling up, integrating new tools, or adapting your workflows DDM bends without breaking. It’s agile enough to fit your business, and robust enough to support it as you grow.

Streamline Product Development with DDM PLM

Accelerate innovation, ensure compliance, and take control of your product data with DDM’s powerful PLM platform — trusted by regulated industries worldwide.

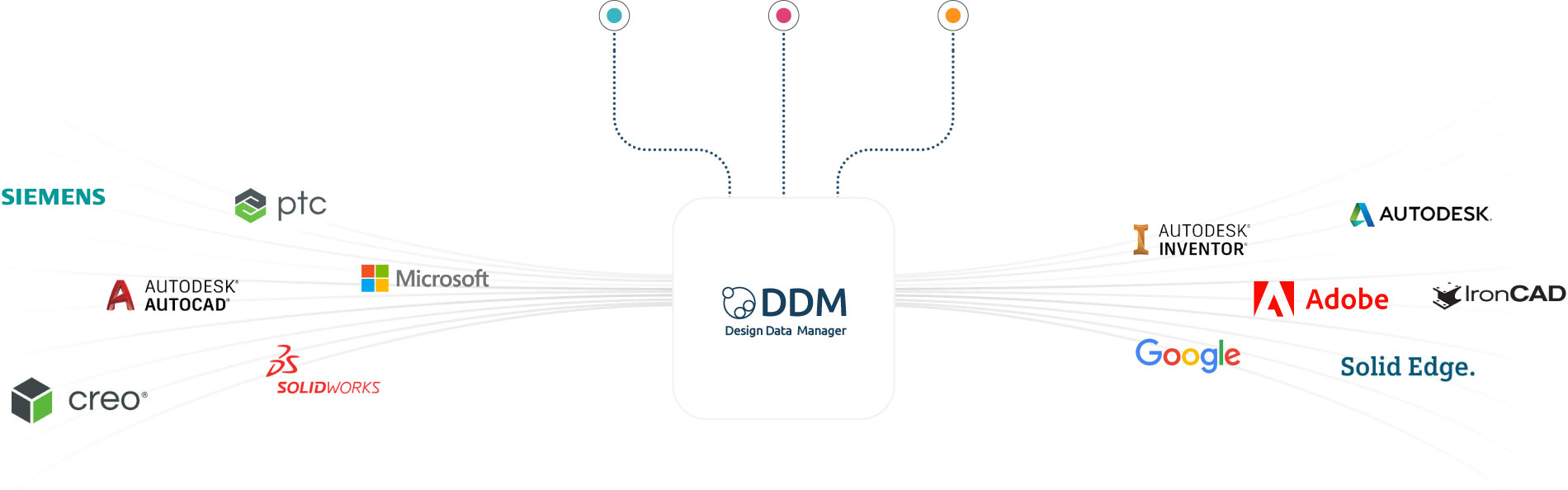

DDM connects your ecosystem to your users

Secure data and full revision history to automated workflows,

document previews, and real-time project visibility

For CAD Users

Engineers, Designers, Editors

Handle the full design lifecycle from inside your CAD environment.

- Multi-CAD integrations (3D & 2D)

- BOM management and comparison

- ERP/MRP integration

- Product structure editing

- Workflow editor

For Office Users

Admins, Approvers, Internal Teams

Coordinate and control projects without needing CAD software.

- Edit BOMs and non-drawn parts

- Manage product structures (CAD-free)

- Assign tasks and track progress

- Run approvals and change processes

- Handle documents in one place

For Web Users

Viewers, External Teams, Supply Chain

Stay informed and connected from anywhere, instantly.

- Read-only access to approved data

- View file history, audits, PDFs

- Access via any browser, no install

- Optional write access

What our users think

Brilliantly easy & brilliantly powerful

Trusted by thousands of industry leaders to deliver time-saving value across sectors — from defence to healthcare and beyond.

“We struggled for years with a paper system until we implemented DDM. Data management has become second nature, everything is stored and completed in DDM”

“It’s been very impressive! The ability of DDM to be very quickly adapted and configured to meet our business needs. It goes beyond just data control and CAD…”

Frequently Asked Questions

FAQs

Whether you’re exploring DDM for the first time or looking to get more out of your current setup, this FAQ covers the most common questions about our platform, integrations, setup, and support.

If you don’t see what you’re looking for, our team is always here to help.

DDM is built for engineers, designers, and manufacturers who use tools like SOLIDWORKS, AutoCAD, Creo, and Siemens NX. It’s especially valuable for small to mid-sized businesses looking for scalable data control without expensive IT overhead.

DDM is built for engineers, designers, and manufacturers who use tools like SOLIDWORKS, AutoCAD, Creo, and Siemens NX. It’s especially valuable for small to mid-sized businesses looking for scalable data control without expensive IT overhead.

DDM is built for engineers, designers, and manufacturers who use tools like SOLIDWORKS, AutoCAD, Creo, and Siemens NX. It’s especially valuable for small to mid-sized businesses looking for scalable data control without expensive IT overhead.

DDM is built for engineers, designers, and manufacturers who use tools like SOLIDWORKS, AutoCAD, Creo, and Siemens NX. It’s especially valuable for small to mid-sized businesses looking for scalable data control without expensive IT overhead.

DDM is built for engineers, designers, and manufacturers who use tools like SOLIDWORKS, AutoCAD, Creo, and Siemens NX. It’s especially valuable for small to mid-sized businesses looking for scalable data control without expensive IT overhead.

DDM is built for engineers, designers, and manufacturers who use tools like SOLIDWORKS, AutoCAD, Creo, and Siemens NX. It’s especially valuable for small to mid-sized businesses looking for scalable data control without expensive IT overhead.

Streamline Product Development with DDM PLM

Accelerate innovation, ensure compliance, and take control of your product data with DDM’s powerful PLM platform — trusted by regulated industries worldwide.